The photovoltaic effect

|

|

Photovoltaic technology

allows to directly convert energy from solar radiation directly into electric energy, with an overall

efficiency![]() between 16% and 18% for a single monocrystalline photovoltaic

cell

between 16% and 18% for a single monocrystalline photovoltaic

cell ![]() .

.

This technology makes use of the photovoltaic effect which is based on the properties of certain semiconducting materials which can convert solar radiation energy into electric energy without the use of moving mechanical parts and without the use of fuel (Fig. 1).

These devices are made from

semiconductor![]() ,

materials, such as

silicon

,

materials, such as

silicon![]() (Si), gallium arsenide (GaAs) and copper sulphate (Cu2S). In a photovoltaic cell

(Si), gallium arsenide (GaAs) and copper sulphate (Cu2S). In a photovoltaic cell![]() , the

photons

, the

photons![]() of the incidental solar radiation break the ties of the semiconductor's electrons, thus

allowing the electrons to move freely in the semiconductor. The positions left

free by the electrons act as positive charges and take the name of "holes". The

photovoltaic cells generally consists of two thin regions, one above the other,

each with specially added impurities called dopants. The result is that one

region is of "type n"

of the incidental solar radiation break the ties of the semiconductor's electrons, thus

allowing the electrons to move freely in the semiconductor. The positions left

free by the electrons act as positive charges and take the name of "holes". The

photovoltaic cells generally consists of two thin regions, one above the other,

each with specially added impurities called dopants. The result is that one

region is of "type n"![]() , with an excess of electrons (negative), while the other is

of "type p", with an excess of positive holes. This 2-region structure, called a

p-n junction, produces an internal

electric

field

, with an excess of electrons (negative), while the other is

of "type p", with an excess of positive holes. This 2-region structure, called a

p-n junction, produces an internal

electric

field![]() . When the

photons create free electrons and holes in proximity to the p-n junction, the

internal electric field makes them move in opposite directions: the electrons

move towards the side n and the holes move towards the side p. So a tension (electromotive

force, e.m.f.) is generated between the p and n regions, with p positive and n negative.

Using wires, the side p and n are connected to a "load",

e.g. a light bulb, and an electric

current runs through the load.

. When the

photons create free electrons and holes in proximity to the p-n junction, the

internal electric field makes them move in opposite directions: the electrons

move towards the side n and the holes move towards the side p. So a tension (electromotive

force, e.m.f.) is generated between the p and n regions, with p positive and n negative.

Using wires, the side p and n are connected to a "load",

e.g. a light bulb, and an electric

current runs through the load.

|

|

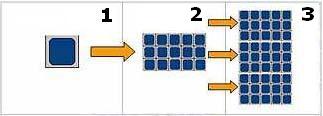

Silicon in crystalline form is the

material most commonly used to make photovoltaic cells, which typically measure

12cm x 12cm. The cells are assembled together to obtain

photovoltaic

modules![]() with a surface of approximately half a metre squared (Fig. 2).

with a surface of approximately half a metre squared (Fig. 2).

Other types of cells are those in polycrystalline and amorphous silicon, which

are not as efficient, and those with more than two junctions, which are more

efficient but also more expensive. At the moment considerable efforts are being

made to develop plastic cells with polymers, which should have lower costs but

also reduced efficiency.

Photovoltaic systems are made

up of many panels connected in series and in parallel; this modularity permits

the systems to be highly flexible. A photovoltaic system can be a

stand

alone![]() system or a

grid

connected

system or a

grid

connected![]() ) system.

In both cases it is necessary to convert the continuous electric current supplied by the cells into alternate current through the use of an

inverter

) system.

In both cases it is necessary to convert the continuous electric current supplied by the cells into alternate current through the use of an

inverter

![]() .

.